The world of chocolate-making is a blend of artistry and science, where every step is crucial in delivering the silky, flavorful treats that delight taste buds around the globe. Behind the scenes of this intricate process, a critical yet often overlooked player ensures the flawless movement of chocolate from one stage to another—the chocolate transfer pump.

But what exactly is a chocolate transfer pump, how does it work, and why is it essential for chocolate manufacturing? This blog will explore these questions while shedding light on why quality chocolate pumps can make all the difference for chocolate-making operations.

What is a Chocolate Transfer Pump?

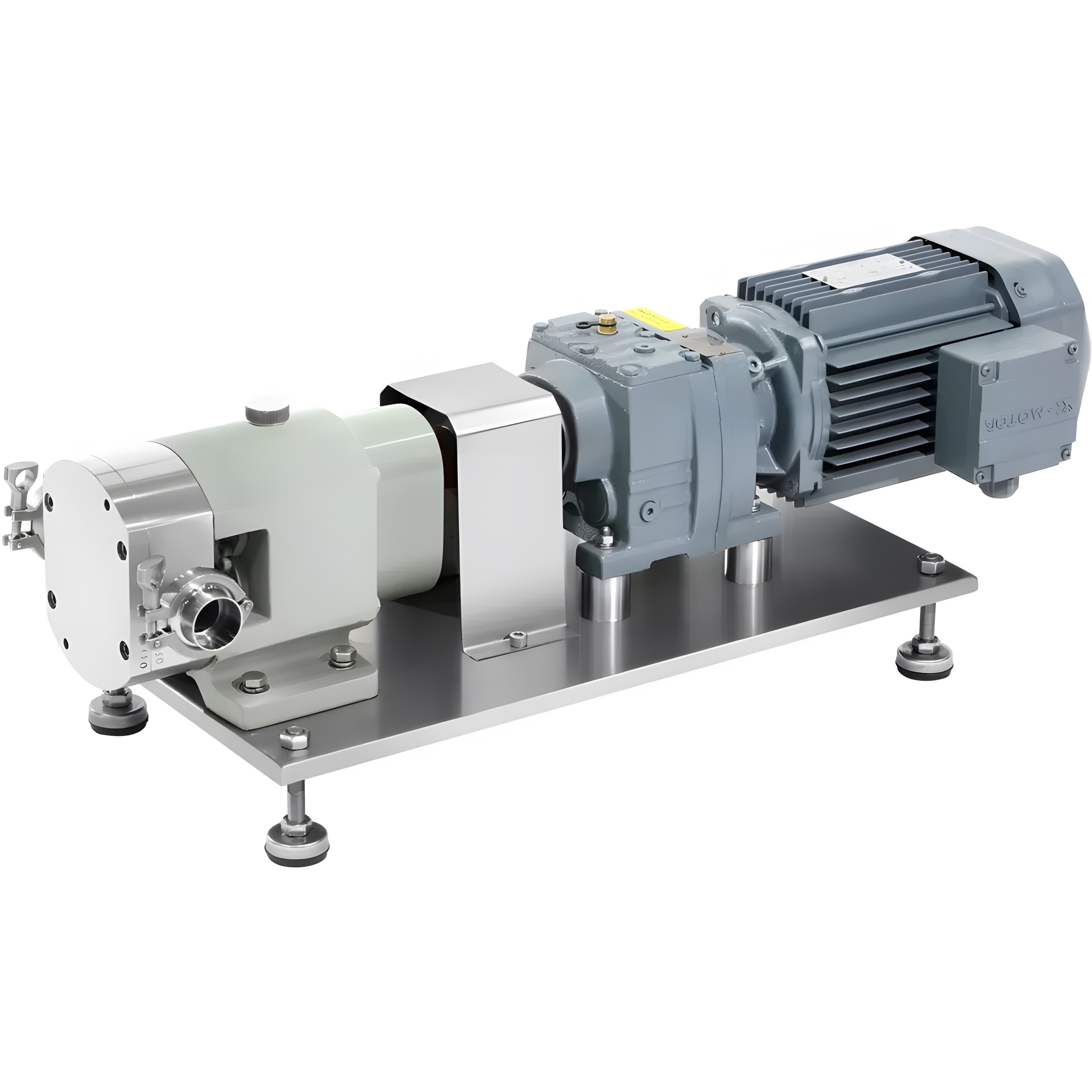

A chocolate transfer pump is a specially designed piece of equipment used in the chocolate production process to transfer chocolate efficiently between different stages, tanks, or machines. Unlike standard industrial pumps, chocolate transfer pumps are tailor-made to handle the unique properties of chocolate, such as its viscosity, sensitivity to temperature, and propensity to crystallize.

Key Features of Chocolate Pumps:

- Heat jackets or temperature controls: These ensure the chocolate stays within the ideal working temperature range, preventing solidification or overheating.

- Gentle handling: Chocolate pumps transfer chocolate without altering its texture or consistency.

- Compatibility with high viscosity: The pumps are engineered to handle chocolate’s thick, semi-solid state with minimal effort.

These pumps also come in a variety of designs, including rotary lobe pumps, gear pumps, and diaphragm pumps, each catering to specific processing needs.

How Chocolate Transfer Pumps Work

The process of moving chocolate through a facility may seem simple, but maintaining the product’s integrity during transfer is critical. Chocolate pumps play a significant role in this by ensuring efficient movement while preserving the silky texture and flavor chocolate-makers work hard to achieve.

The Chocolate Pumping Process

- Drawing the Chocolate: Chocolate enters the pump chamber, fed either from melting tanks, tempering machines, or holding tanks.

- Maintaining Temperature: To ensure the chocolate remains in its liquid state, the pump uses heat jackets to maintain consistent temperature.

- Efficient Transfer: The pump’s mechanisms—often rotary lobes or gears—move the chocolate through pipes or hoses seamlessly to the next destination, such as depositing machines or enrobing lines.

- Minimal Shear Stress: The pump’s gentle operation prevents overmixing or aeration, which could negatively affect the product’s texture or temper.

One of the standout traits of quality pumps is their ability to provide consistent, clog-free operation regardless of the thickness or formulation of the chocolate.

Example of Application in Chocolate Factories

For instance, chocolate pumps are essential when moving liquid chocolate to coating stations. They ensure a steady flow without introducing air bubbles, preserving the glossy finish on chocolate bars and confections.

Why Chocolate Transfer Pumps Are Essential

Chocolate manufacturing demands precision and consistency. Here’s why chocolate pumps are indispensable in meeting these requirements.

-

Maintains Quality

Chocolate’s delicate structure makes it susceptible to changes in texture, flavor, and appearance if not handled correctly. Chocolate pumps are designed to handle ingredients gently, reducing the likelihood of defects like bloom (where fat crystallizes on the surface) or inconsistent tempering.

- Improves Efficiency

The alternative to pumps—manual transfer or using unsuitable equipment—can lead to spillage, wastage, and slowed production times. Chocolate pumps automate this process, ensuring seamless transfer and saving valuable time for the production team.

-

Preserves Hygiene Standards

High-quality pumps are constructed using food-grade, stainless steel materials that ensure compliance with strict hygiene regulations. Additionally, many are designed for easy disassembly and cleaning, reducing the risk of contamination.

-

Handles High Viscosity Smoothly

Chocolate is notoriously thick and sticky, which can create challenges for standard pumps. Chocolate pumps are built to handle this viscosity without clogging, preventing production disruptions.

-

Enables Versatility in the Production Line

Whether you’re manufacturing chocolate bars, truffles, or enrobed treats, chocolate pumps adapt to various applications. Their precision makes them suitable for different types of chocolate products.

Quick Statistic

According to a market research report, the global chocolate market was valued at over $100 billion in 2023, highlighting the growing demand for efficient production technologies like chocolate transfer pumps.

Features to Look for in a Quality Chocolate Pump

Choosing the right chocolate pump for your operation is critical to maximizing efficiency and product quality. Here are the key features to consider when selecting one:

-

Temperature Control Capabilities:

Ensure that the pump includes heat jackets to maintain optimal chocolate temperature.

-

Material and Build Quality:

Look for pumps made from food-grade stainless steel to ensure safe handling of edible products.

-

Ease of Maintenance:

Select a pump with easy cleaning and disassembly features to meet hygiene standards and minimize downtime.

-

Flow Rate and Customization:

Evaluate the pump’s flow rate to ensure it can handle your facility’s production volume and customize settings based on different product needs.

-

Durability and Longevity:

Invest in a pump known for its reliability and robustness, minimizing long-term maintenance costs.

Working with a trusted supplier can help you find the perfect pump tailored to your facility’s specific needs.

Future Trends in Chocolate Pumping Technology

The world of chocolate-making continues to evolve, and chocolate pump technology is no exception. Newer models incorporate cutting-edge innovations like AI-driven monitoring systems, which automatically detect potential blockages or irregularities in the pumping process. These advancements promise to further enhance efficiency and precision in manufacturing.

Additionally, increased focus on sustainable manufacturing practices is driving the development of energy-efficient pumps that reduce the environmental footprint of chocolate production.

The Secret Ingredient to Smooth Operations

Chocolate transfer pumps may not be the first thing that comes to mind when thinking about chocolate production, but their role is indispensable. By maintaining quality, improving efficiency, and ensuring hygiene, these pumps are truly the unsung heroes behind every chocolate masterpiece.